Direct Digital Manufacturing: polymers and composites

Additive Fabrication is an advanced manufacturing technology in which the three-dimensional objects are built through the addition of material in a layer-by-layer fashion. The produced objects can be functional or simply serve for an conceptual evaluation of the desired product being development.

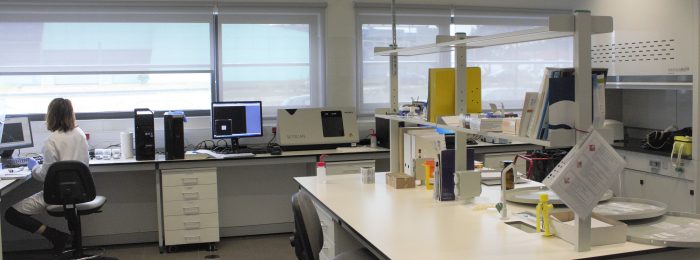

The Additive Manufacturing Laboratory is a space with equipment dedicated to the rapid automatic fabrication of physical objects.

|

Laboratory 360 view ( Must log in your Google account for a 360 view ) |

Equipment:

|

uPrint

Description:

The additive manufacturing technique that uses this equipment is FDM (Fused Deposition Modeling). Ecological: work is a clean. It is considered e technology of “office”.

Specifications:

Dimension: 570 x 620 x 800 mm

Weight: 76 kg

Construction volume: 203 x 152 x 152 mm

Material:

Model: ABS Plus (termoplastic material)

Support: material after constructions of the finished part, is dissolved at a bath temperature ± 70ºC

Vflash

Description:

The additive manufacturing technique that uses this equipment is FTI (Film Transfer Imaging). Technology is considered an “office”. Construction of models in high quality. Accessible, fast and easy hardling.

Specifications:

Dimension: 660 x 685 x 787 mm

Weight: 66 kg

Construction volume: 228 x 171 x 203 mm

Layer thickness: 102µm

Material:

FTI-GN Material

Density: ~ 1.11 g/cm3

Tensile Strength: 33 MPa

Tensile Modulus: 1550 MPa

Elongation: 5.0%

Flexural strength: 53 MPa

Flexural modulus: 1700 MPa

UP

Description:

The additive manufacturing technique that uses this equipment is FDM (Fused Deposition Modeling). This equipmemt allows us to make colored pieces. It is considered an educational technology. Accessible, fast and easy hardling.

Specifications:

Dimension: 245 x 260 x 350 mm

Weigth: 5 kg

Construction volume: 140 x 140 x 135 mm

Layer thickness: 0.2, 0.25, 0.3, 0.35, 0.4 mm

Material: ABS Plastic (write)

BFB

Description:

The additive manufacturing technique that uses this equipment is FDM (Fused Deposition Modeling). This equipmemt allows us to make colored piecess. It is considered an educational technology. Accessible, fast and easy hardling.

Specifications:

Dimension: 600 x 600 x 700 mm

Weight: 38 kg

Construction volume: 100 x 100 x 210 mm (ABS) | 200 x 200 x 210 mm (PLA)

Material:

ABS (thermoplastic material)

PLA (biodegradable thermoplastic)

Zprint

Description:

Most Affordable, Quality 3D Models, Monochrome.

Specification:

Dimension: 740 x 790 x 1400 mm

Weight: 165 kg

Build size: 236 x 185 x 127 mm

Color: Monochrome (write)

Resolution: 300 x 450 dpi

Minimum feature size: 0,4 mm

Layer Thickness:0,1 mm

Number of jets: 304

Material:

High performance composite